Blogs

Our Blog Posts

The Evolution of Warehouse Storage

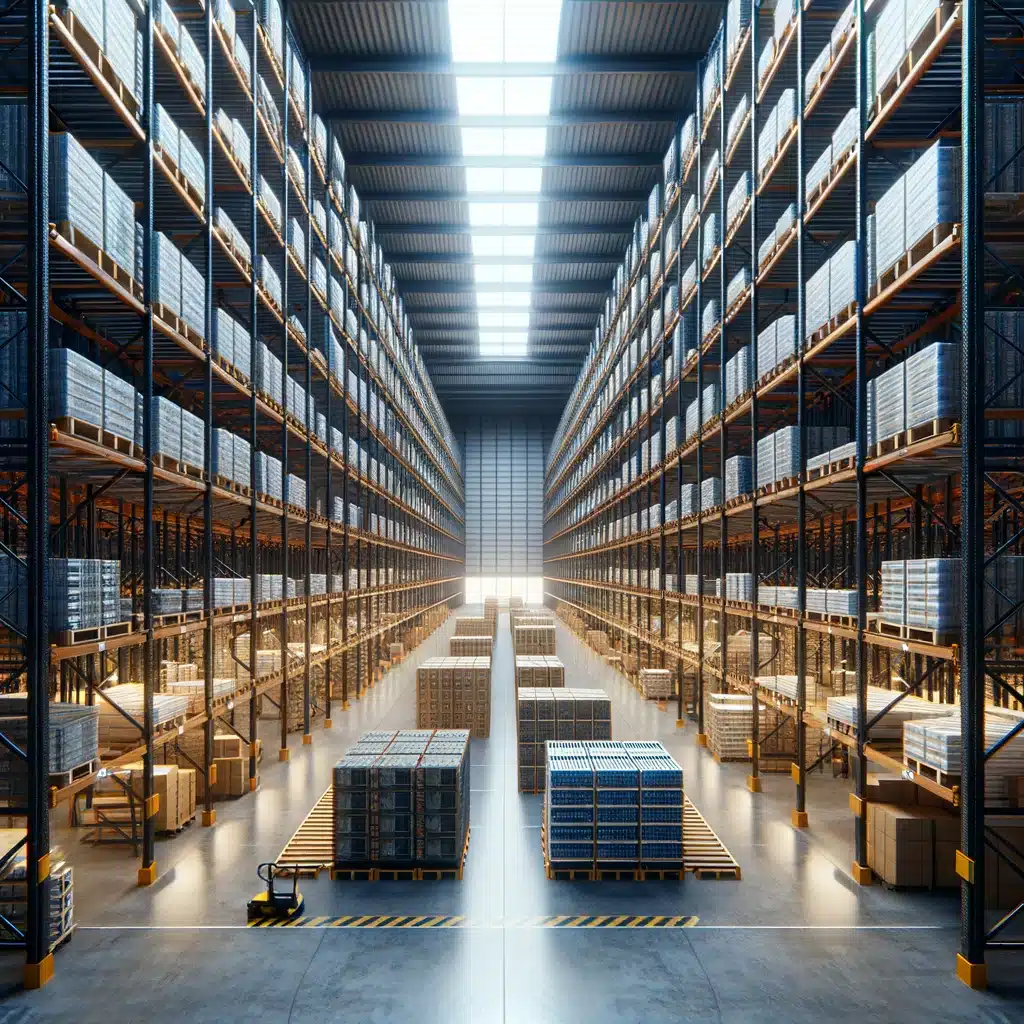

Conventional storage techniques have given way to more advanced alternatives designed to satisfy the needs of contemporary logistics in warehouse storage. Industrial pallet racks are a key invention that has completely changed how warehouses keep track of their goods. The days of disorganized aisles and wasteful space use are long gone. Pallet racking systems provide a methodical method of storing items, enabling warehouses to optimize their vertical space while preserving accessibility. The physical advantages of this space optimization include more storage capacity, faster handling times, and better inventory control.Why Should You Have a Pallet Racking System In a Warehouse?

Pallet racking systems help in many ways in warehouses and sometimes the industrial sector needs to install pallet racking systems to optimize their storage capabilities, apart from this, let's discuss some primary reasons why should we have Industrial pallet racks: Lack of Space: Pallet racks are the ideal option if you discover that you're lacking in square footage to store your products and oversee productivity! With the help of these racks, you may safely and conveniently stack your merchandise, maximizing the vertical square footage of your warehouse. Employee Accidents: A workplace accident involving an employee might spell disaster for your whole company! A worker may have significant injuries that prevent them from returning to work, insurance costs may increase, legal action may be taken against you, and employee morale may suffer as a result of the incident. Pallet racking systems reduce clutter and personnel dangers, which are major advantages for a warehouse with plenty of moving parts. Damaged Inventory: It's obvious that something needs to change if your warehouse is filled with damaged goods as a result of your present inventory management procedures! These losses may result in shortages and wasted inventory, which will have an impact on your earnings. Pallet racks allow you to set aside enough room for each pallet so that you are not forced to stack goods on top of one another. EMC Installation provides a safer work environment and significantly lowers the possibility of damaged items.Install Your Industrial Pallet Racks To Optimize Space And Safety

In the event of a collision, our pallet racking keeps the pallet racking from potentially collapsing. To prevent mishaps during pallet handling and storage, we install Pallet Racks that are attached to the back of the pallet racking. This enhances the security of pedestrians beneath it. To ensure that the shelving conforms with health and safety laws, EMC Installation inspects and maintains your pallet warehouse racking. Individual rack components can be changed if some portions don't meet regulations. Pallet racking raises safety, but this level of protection needs to be maintained. Readmore - Understanding the Pallet Racking SystemWhat is a Pallet Racking System

Racked are buildings made to hold palletized products on rows of horizontal shelves with varying height levels. Their arrangement in the warehouse creates a series of lanes where products are stored and retrieved from the racking positions by operators using forklifts, also known as automatic handling equipment. EMC Installation offers pallet racks that help to organize warehouse space better than just placing pallets on the ground or piling them on top of one another. Pallet racking ensures effective inventory distribution and is commonly used by businesses whose items are distributed to several locations.What are the Components Of a Pallet Rack

Upright Frames: The bracing that runs across or diagonally between the two posts holds the two metal columns that make up the upright frame together. For the horizontal beams to join and lock into place, the columns have holes bored into the metal, usually in the shape of a teardrop, keyhole, or T shape, for the horizontal shelf to secure and close in. Horizontal Shelf: The real pallet shelves are formed by the sturdy, weight-bearing rails that make up the pallet rack beams, which fasten to the upright frames. In addition to supporting the pallets themselves, these horizontal beams come in a range of heights and lengths to accommodate a range of weight and capacity needs.What Are The Advantages Of Various Types Of Pallet Racking?

Pallet racking can be broadly classified into two types: high-density systems and those that permit direct product access. Direct-access systems have the advantage of making product handling easier and guaranteeing the best possible occupancy of storage space. This category includes: Pallet racking with single-deep selection: The adaptability of these racks makes them unique. They have add-ons and accessories that allow storage places to be customized to fit various unit loads with varying dimensions and features. Pallet racking with adjustable double depth: To maximize storage capacity without compromising easy access to products, racks are stacked one on top of the other. Racking with cantilevers: This is used to handle large, varying-length objects, like profiles. It makes it easier for workers to handle this stuff and keep an eye on every item.Choose the Right Pallet Racking System

EMC installation provides the best features, weight, and handling position of your products are just a few of the many factors that will affect the size and layout of your pallet racks. A further consideration is the handling machinery used to move and position the loads. The racking should be adaptable enough to accommodate various load types while selecting the optimal solution. They ensure that storage complies with quality and security standards by regulating important factors like safety and load capacity.1. Layout Optimization

The first step in efficient warehouse storage is designing an optimized layout. Consider factors such as the size and shape of the warehouse, the types of goods being stored, and the flow of operations. A well-designed layout minimizes the distance traveled by workers and vehicles, reducing the time and effort required to pick, pack, and ship orders.2. Vertical Space Utilization

Maximize your storage capacity by utilizing vertical space. Install tall shelving units or invest in pallet racking systems to store goods vertically. This not only increases storage capacity but also allows for better organization and accessibility. Make sure to use sturdy materials and proper safety measures to prevent accidents and injuries.3. ABC Analysis

Implement the ABC analysis method to prioritize inventory storage based on demand. Classify items into three categories:- A items: High-value items with low demand frequency

- B items: Moderate-value items with moderate demand frequency

- C items: Low-value items with high demand frequency

4. FIFO and LIFO

Adopt the FIFO (First-In-First-Out) or LIFO (Last-In-First-Out) method, depending on the nature of your products. FIFO ensures that older inventory is sold or used first, reducing the risk of product spoilage or obsolescence. LIFO, on the other hand, may be more suitable for non-perishable goods or products with longer shelf lives.5. Labeling and Signage

Maintain clear and consistent labeling throughout the warehouse. Use barcode or RFID technology to track inventory and facilitate accurate picking and replenishment. Additionally, use signage to indicate aisle numbers, storage locations, and safety instructions. Well-labeled warehouses improve navigation and minimize errors.6. Regular Audits and Reviews

Conduct regular audits and reviews of your warehouse storage practices to identify areas for improvement. Analyze inventory turnover rates, space utilization, and picking accuracy. Solicit feedback from warehouse staff to understand pain points and implement solutions accordingly.7. Embrace Technology

Invest in warehouse management systems (WMS) and inventory management software to streamline operations and improve accuracy. These systems can automate tasks such as order processing, inventory tracking, and replenishment, freeing up valuable time for warehouse staff to focus on higher-value activities. By implementing these strategies, businesses can optimize warehouse storage, improve efficiency, and ultimately deliver better service to customers.Understanding Racking Systems

Racking systems are designed to store materials and objects vertically while facilitating easy inventory access to maximize floor space. Variations available for these systems include shelving systems, mezzanine platforms, cantilever racking, and pallet racking; each is intended to satisfy specific storage requirements and architectural constraints. Pallet racking, for instance, is widely used to store palletized goods and offers a range of options, such as drive-in, push-back, and selective racking, to fit various inventory profiles. On the other hand, cantilever racking is the ideal method for storing long, heavy items like timber, pipes, and sheet metal. Rack systems' adaptability and scalability make them a priceless tool for businesses trying to optimize their storage capacity.The Importance of Professional Installation Services

Professional racking installation services from licensed and certified installers ensure that racking systems are assembled and secured according to industry standards and safety regulations. Let's discuss some key considerations when hiring a professional racking installer. Knowledge and Experience: With years of experience in racking systems, make your installation risk-free. We ensure the safe and efficient installation of racking systems, lowering the risk of mishaps or structural collapse. Optimized Space Utilization: We carefully configure racking systems to increase storage capacity while preserving accessibility and efficiency, allowing you to make the most of available space inside a building. Effective Project Management: Racking installation projects need careful planning and coordination. Expert installers are superb project managers; they supervise every installation procedure step from beginning to end and keep stakeholders informed at every stage of the project's lifecycle.Choosing the Best Racking Installation Services

EMC Installation fulfills specific requirements, so choosing them as your go-to Calgary racking installation service provider might be wise. Here are some reasons why EMC Installation can be the most excellent option for your Calgary racking installation needs: Local Presence: There are several benefits to using a Calgary-based racking installation service provider. Their familiarity with building rules, industry standards, and local legislation can facilitate the installation procedure and guarantee adherence. Flexibility and Customization: EMC Installation provides choices for customizing its services to meet your unique demands and spatial constraints. This adaptability can guarantee that their racking system precisely fits your storage objectives and limitations. High-quality Materials and Workmanship: Evaluate the materials we used to install their racking. High-quality components and expert construction are necessary for your racking system to last a long time and be safe. Safety Standards and Compliance: Verify that EMC Installation complies with all applicable safety guidelines. Comprehensive safety standards must be in place to reduce installation-related dangers and guarantee the security of both workers and residents. Cost-Effectiveness: Value should be given precedence above price, even while cost is a consideration. Consider the total service quality, dependability, and long-term robustness with our racking system installer. Customer Service and Support: A business that offers top-notch customer care and continuous assistance can facilitate the installation procedure and quickly resolve any problems that may come up.Conclusion

EMC is a reputable installation service provider. Businesses can optimize their space utilization, improve workflow efficiency, and ultimately drive corporate success by ensuring that their racking systems are erected safely, effectively, and according to industry standards.Pallet racking systems are integral to maximizing storage space and efficiency in warehouses. Installations EMC specializes in providing bespoke racking solutions tailored to the unique needs of each facility.

Why Choose Installations EMC?

Installations EMC stands out for its commitment to quality, customization, and customer satisfaction. Our team ensures that every installation meets the specific operational needs of our clients.

The Installation Process

Initial Assessment

Our journey begins with a detailed assessment of your space and storage needs, allowing us to understand the challenges and opportunities within your warehouse.

Customized Design

Leveraging advanced software, our team designs a pallet racking system that optimizes every inch of your warehouse, ensuring both efficiency and safety.

Expert Installation

Our certified professionals handle the installation, adhering to the highest industry standards to ensure durability and reliability.

Beyond Installation

Safety and Compliance

We prioritize the safety of your operations, ensuring all installations meet rigorous safety standards and regulations.

Maintenance and Support

Installations EMC provides ongoing maintenance and support, ensuring your racking systems remain in peak condition to support your business's growth.

Case Studies: Success Stories

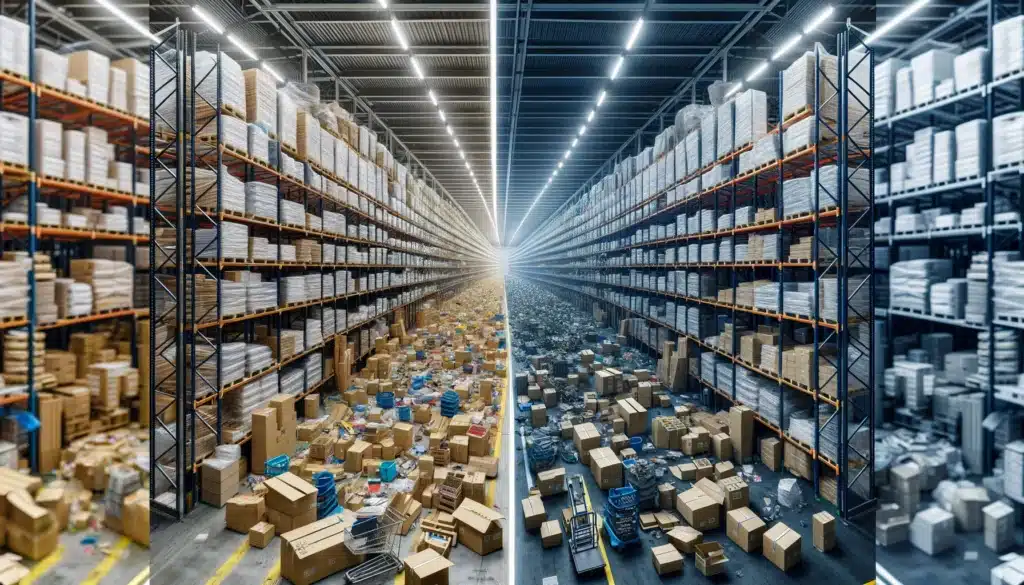

Transforming Warehouse A

A before-and-after scenario where Installations EMC redefined the storage capabilities of a previously cluttered warehouse, significantly enhancing its operational efficiency.

Maximizing Space in Warehouse B

A showcase of how Installations EMC's innovative solutions doubled the storage capacity of a medium-sized warehouse without compromising accessibility.

Why Pallet Racking is a Game-Changer

Enhanced Space Utilization

Discover how pallet racking systems can transform wasted vertical space into a valuable storage asset.

Improved Efficiency and Productivity

Learn about the direct correlation between well-organized storage solutions and increased operational efficiency.

Conclusion:

Elevate Your Warehouse with Installations EMC

Ready to Transform Your Space?

Contact Installations EMC today to explore how our pallet racking solutions can revolutionize your storage capabilities and operational efficiency.